As I mentioned in the January Energy report, heating with firewood would not make economic sense except for the fact that we have a good supply of free firewood. I'm planning to burn about 1 cord of wood per year in the coldest weather so I decided to build a woodshed that would hold two cords... one cord of seasoned wood for the current winter and one cord of 'green' wood for the next.

Recall that a cord is a stack of wood four feet deep, four feet high and eight feet wide (128 cubic feet). I decided to make the shed 16 feet wide and four feet deep; divided into two 8-foot sections.

Since the shed will be next to the driveway and close to the carport for convenience It wanted it to have a 'modern' look that would blend with the style of the house.

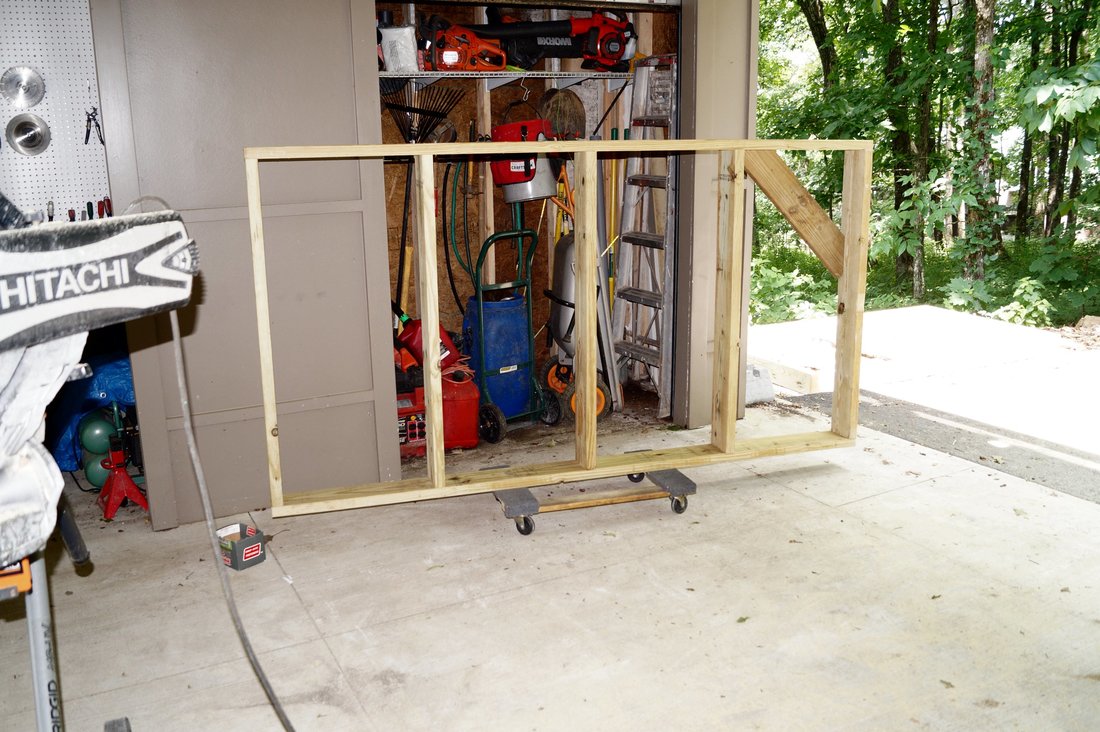

Since I'm working alone I had to come up with a modular design that could be assembled in manageable sections.

I built the floor out of pressure-treated (PT) 2x6's in 4-foot by 8-foot sections. I build each "module" on the carport floor to ensure that they are flat and square and then rolled them into place.

Once the two floor modules were in place, I jacked them level and then installed support posts.

The wall modules are lighter and easy to install.

I am using left-over 16" wide standing-seam steel roofing material as siding. So, the wall modules are 83 1/4" tall, which is 5 rows of siding plus a 2x4 top and bottom plate.

To give the roof a shallow slope (about 1:12), I made a header from double 2x4's standing on edge for the front of the shed. The back of the rafters rest directly on the wall plate and the fronts are elevated by 3 1/2 inches. Note that the roof slopes to the back of the shed so the rain won't be draining on my head when I go out to get wood.

As mentioned, I am using left-over roofing material for siding. I'm installing it horizontally to create a 'modern' profile. I painted the exterior of the frame to match the house before installing the siding. That way I could be a sloppy painter and didn't have to mask the metal panels.

Note, the top row of siding has been left off at this point to make it easier to install the roof.

The roof is Palram clear poly carbonate. It is strong yet very lightweight. I'm hoping that the sun will help dry the wood. Note the spacing between the floorboards is to allow air circulation.

The rear of the poly carbonate extends 2 inches past the framing so a rain gutter can be installed in the future.

All done and ready for Winter 2018 !!

RSS Feed

RSS Feed